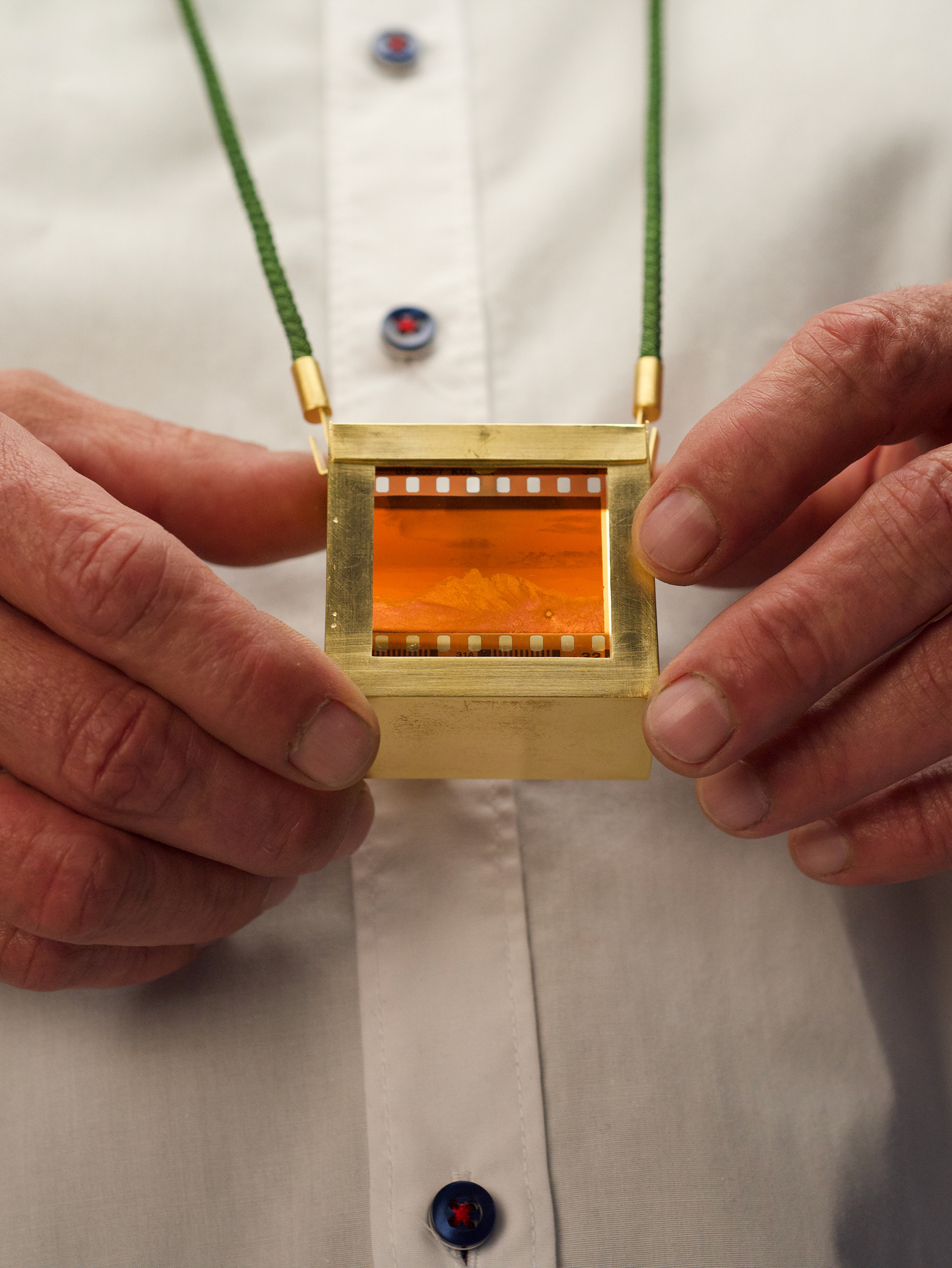

Necklace I - Brass wire

Machines do not make mistakes. . .

. . . do they?

Even in the most efficient production of goods, waste is generated, material residues that cannot be used any further. In certain cases, these can be recycled again, but always causing additional energy consumption.

But what if?

What if the “non-perfect”, the random product, was not regarded as waste that has to be processed into raw material again, but as something new, something that can be used creatively for a new purpose? In other words: take a step back and look at this out-of-sequence object with new eyes? Instead of being thrown away, throw it back “into the head”, as a creative starting point for something new.

During a factory tour at Binder Gmbh in Pforzheim, my attention was captured by the mistakes, the waste that is created during production. I discovered that some of these pieces had a very special, almost unique design language. Fascinating: Through the casualty of error, perfectly programmed machines can produce unique pieces.

Necklace I - Brass wire

Necklace I - Brass wire

Necklace I - Brass wire

The breakdown of an eyelet winding machine was the inspiration for my first model: a chain that owes its design feature to the tension of skew-wound oval eyelets. The individual links of the chain are made of coiled wire. The tension created by the winding causes the double helix-like coiling. The result is a very special feel that could not be achieved by a simple wire.

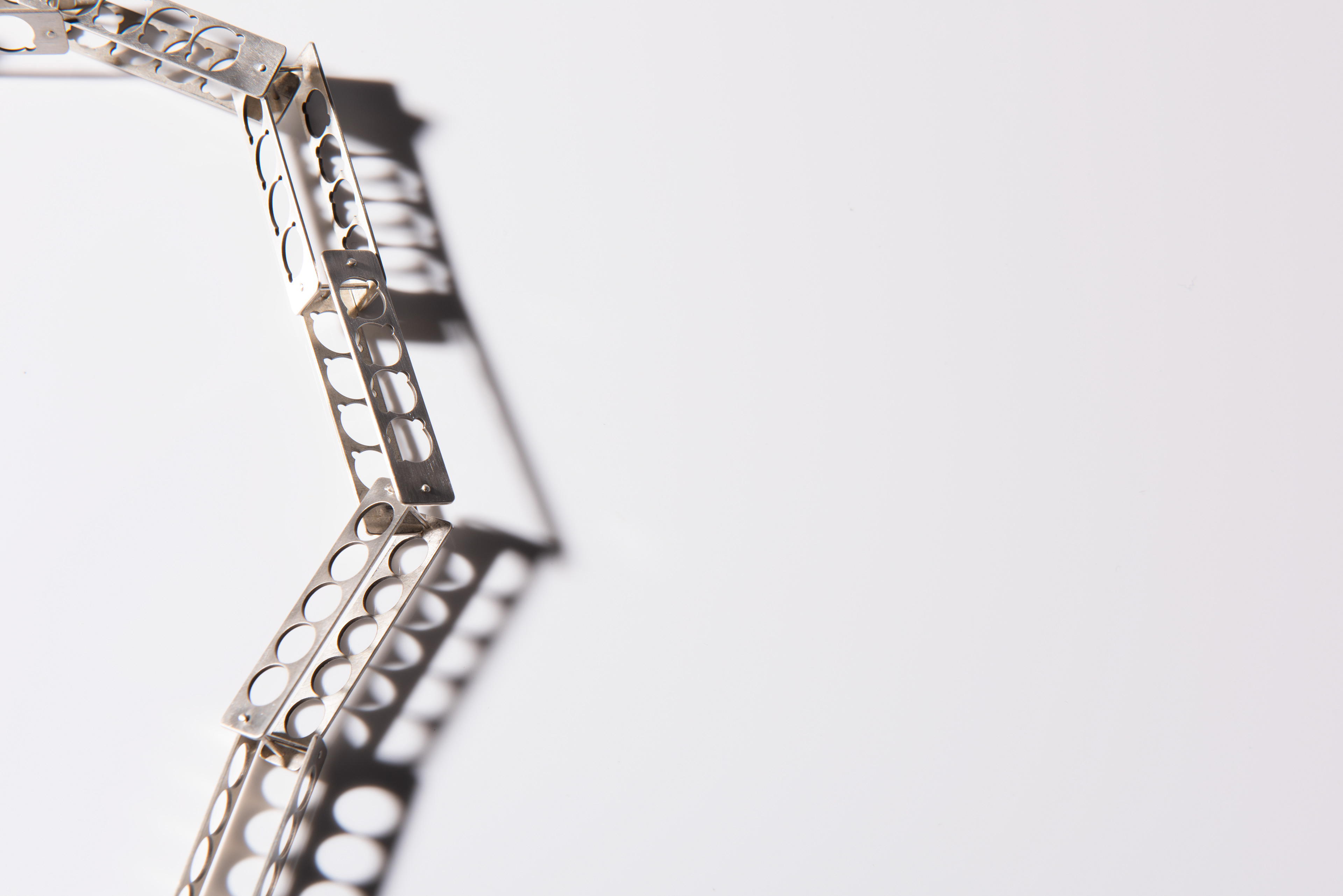

Necklace II - Recycled Silver

Another inspiration for me was the waste produced by laser cutting. The combination of geometric shapes had already captivated me during my first visit to the factory.

Why destroy such an interesting shape and melt it down again?

Cutting the so-called waste in stripes and riveting it, I made three basic chain designs, which can be combined as desired.

Necklace II - Recycled Silver

Necklace II - Recycled Silver

Necklace II - Recycled Silver

Necklace II - Recycled Silver

Necklace II - Recycled Silver

Necklace II - Recycled Silver

In the first model, all the links are oriented in the same way, so the chain is rather flat and has a certain stiffness because the individual elements can only move in one direction.

Therefore, I had to think of an alternative for the back part of the chain.

By sawing the individual metal strips apart and partly riveting them together, partly just soldering them together I obtained a more flexible chain that can be worn comfortably around the neck.

Of course, one could use this kind of connection for an entire piece of jewellery and thus obtain another chain that is much lighter and mobile.

However, the stiffness of the middle links offers an interesting personalization option for the wearer, who can move and bend the elements every time he or she wears them: the stiffness of the rivets causes the chain to retain this shape.

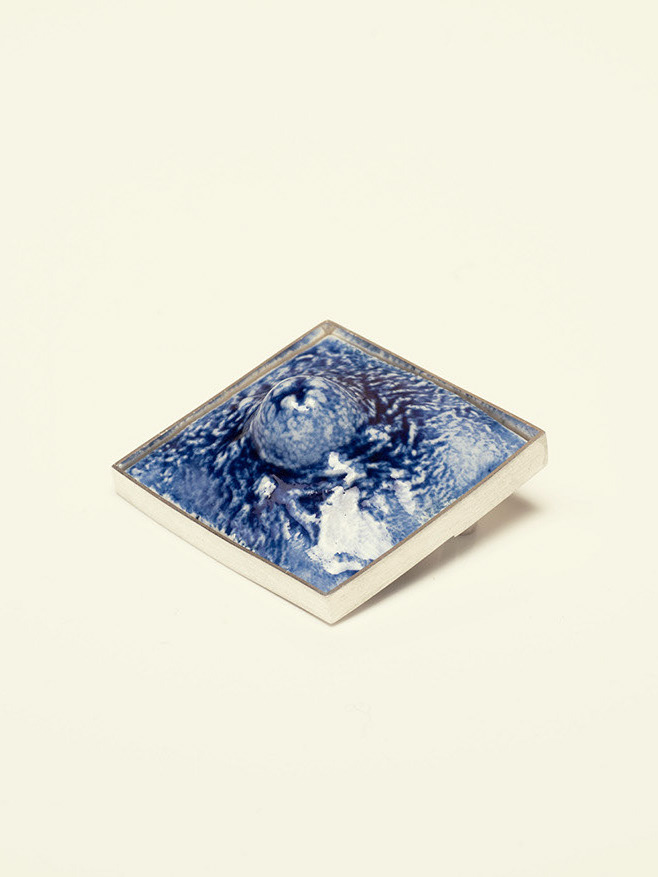

Necklace III - Recycled Silver

Necklace III - Recycled Silver

In the second model, the individual elements are each rotated by 90°, which gives the chain more mobility and allows it to fit snugly around the neck.

In addition, this offers a three-dimensionality all of its own, which not only results in new shapes but can also, depending on the light, create interesting shadow plays on the skin.

Over time, the production of such chains could have an influence on the production cycle: in order to create chain links with the desired look, one could arrange the laser-cut files in order to cut the waste pieces directly, avoiding additional work.

Necklace III - Recycled Silver